Gasket Plate Heat Exchanger | Plate Heat Exchanger manufacturer in India

Gasketed plate-and-frame heat exchangers | Best Heat Exchanger Supplier in India

HS Engineers: Buy Best Alfa Laval Heat Exchanger | Gasketed Plate Heat exchangers manufacturers in india | Plate Heat Exchanger manufacturer in India

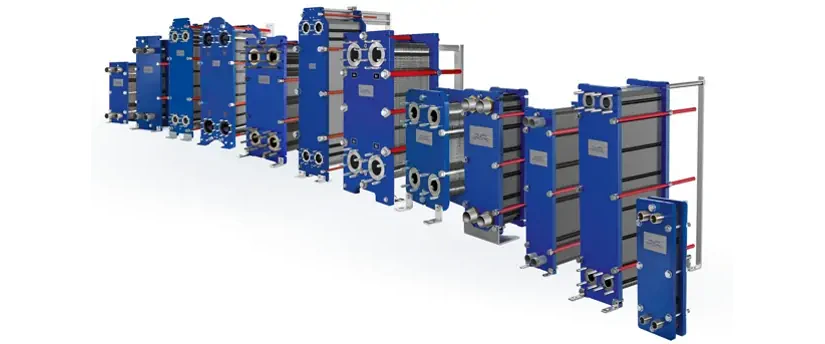

HS Engineers is a trusted high quality gasketed Plate Heat Exchanger manufacturer, supplier, stockist and exporter in India, and we have the widest selection of high-quality, long-lasting products in the market.

The gasketed plate-type heat exchanger, also referred to as Plate & Frame heat exchangers, comprises a set number of stainless steel plates arranged within a frame. These plates feature corrugations to maximize surface area. The patterns pressed into the plates induce turbulence, thereby improving heat transfer. Pressure plates are connected to supporting columns, while gaskets surrounding the plates prevent material leakage both sideways and through the plate holes.

Gasketed plate-and-frame heat exchangers (GPHEs) offer highly efficient heat transfer within a compact framework, boasting a notably smaller footprint compared to traditional shell-and-tube heat exchangers.

The design of plate heat exchangers is geared towards maximizing heat transfer efficacy, owing to the corrugated plates which provide a significantly larger surface area for the exchange of heat between two fluids, be it gases or liquids.

Types of Gasketed Plate Heat Exchangers

Industrial Heat ExchangersThis range offers exceptional versatility, suitable for various industries.

Semi-Welded Industrial Heat ExchangersIdeal for refrigeration applications where gaskets are unsuitable for one of the media, or when higher design pressures are required.

Scraped Surface Heat Exchangers: These specialized exchangers excel in handling viscous fluids and materials prone to fouling, ensuring consistent heat transfer with minimal maintenance requirements.

Tubular Heat Exchangers: Known for their robustness and reliability, tubular heat exchangers are widely used across industries for their ability to handle high-pressure and high-temperature applications.

WideGap Heat ExchangersDesigned for applications involving fibrous liquids, highly viscous fluids, and fluids containing coarse particles.

Diabon Graphite Heat Exchangers Utilized for tough corrosive media, offering durability and reliability.

Applications

FAQ

In a gasketed plate heat exchanger, the plates are fitted with elastomeric gaskets which seal the channels and direct the fluids into alternate channels.

In general, gasketed plate heat exchangers are preferred in industrial settings where flexibility is paramount.

Metal clad gaskets are frequently used with narrow flanges. This combination produces a strong resilient gasket which can be fabricated into complex shapes.

Efficient heat transfer : The units also have a flexible design and are easy to service and maintain. Gasketed plate heat exchangers benefits: Precision heat transfer - closer approach temperature, true counter current flow, 80-90% less hold-up volume.