Brazed plate Heat Exchanger manufacturers in India | Plate Heat Exchanger manufacturer

Alfa Laval Brazed Plate Heat Exchanger | Best Brazed Plate Heat Exchanger Supplier in India

HS Engineers: Buy Best Alfa Laval Brazed Plate Heat Exchanger | Brazed Plate Heat exchangers manufacturers in india | Plate Heat Exchanger manufacturer in India

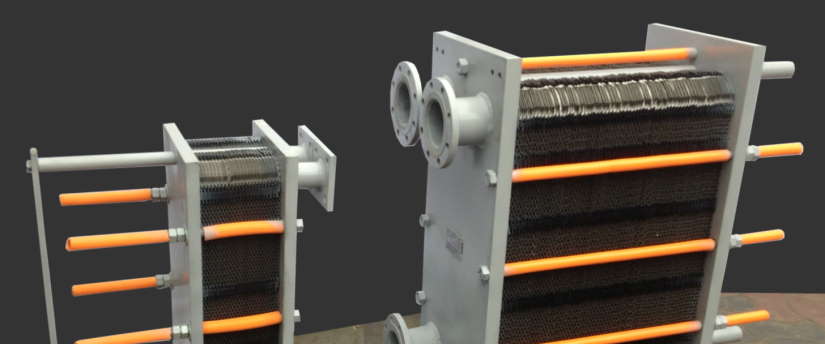

HS Engineers is a reputable manufacturer, supplier, stockist, and exporter based in India, specializing in high-quality gasketed Brazed Plate Heat Exchangers (BPHE). Brazed plate heat exchangers are compact devices that utilize brazing technology to fuse together numerous thin plates, thereby facilitating efficient heat transfer surfaces.

Plate Heat Exchangers Working Principle

Brazed plate heat exchangers comprise a series of ribbed metal plates bonded together through brazing, forming alternating passages for the flow of two different fluids. These plates are typically crafted from materials like stainless steel, copper, or nickel alloys. The brazing technique ensures a robust and leak-proof connection between the plates, guaranteeing dependable performance even under extreme pressure and temperature conditions.

The corrugated design of the plates serves to augment the available surface area for heat exchange purposes. This corrugation induces turbulence in the fluid flow, thereby enhancing the efficiency of heat transfer. The fluids travel in opposing directions through the alternating passages amidst the plates, maximizing the temperature differential and consequently improving heat transfer rates.

Efficient Heat Transfer Solutions

Our lightweight brazed constructions excel in sustainable heat transfer, offering significantly greater thermal efficiency compared to traditional shell-and-tube systems. With a footprint 75% smaller, they maximize space utilization without compromising performance.

In our AC models, the innovative DynaStatic distribution system ensures higher efficiency across various evaporator duties and with any refrigerant. This flexibility enhances overall system performance.

Our solutions are particularly well-suited for use with natural refrigerants. With a compact footprint, optimized plate design, and high design pressure tolerance, they deliver exceptional performance while minimizing environmental impact.

Applications

Brazed plate heat exchangers find widespread application in various sectors including HVAC systems, refrigeration systems, hydronic heating systems, solar water heating systems, domestic hot water systems, and industrial processes.

FAQ

The brazed plate heat exchanger is in principle constructed as a package of corrugated channel plates between front and rear cover-plate packages. The cover-plate packages consist of sealing plates, blind rings and cover plates.

Efficient – With no need for gaskets or supporting equipment, about 95% of the material is used to transfer heat.

Depending on the application, we choose between copper, nickel or VacInox brazed heat exchangers (heat exchangers made of stainless steel).